Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Provide You with the Best Customized Solution!

1. Shredding of Bulky Waste

Introduction to Bulky Waste Crusher

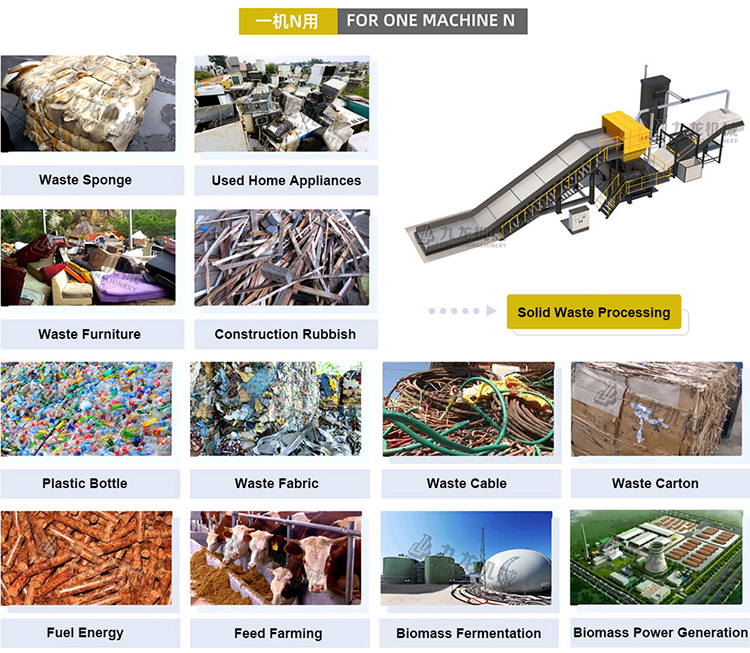

As the quality of life of citizens continues to improve, the upgrading of furniture has also accelerated, resulting in large pieces of garbage such as used sofas, mattresses, old wardrobes, and cabinets. In the past, we might have called recycling companies to clean them up. However, in recent years, the price of waste recycling has dropped, the industry has shrunk, and fewer and fewer people are willing to collect it at home. How to deal with these large pieces of garbage has become a problem that makes people scratch their heads. According to the "Technical Requirements for the Collection and Utilization of Bulky Waste", bulky waste refers to waste that weighs more than 5 kilograms or has a volume greater than 0.2 cubic meters or a length that exceeds one meter and is highly integrated and needs to be dismantled for reuse or processing, including Waste furniture such as discarded sofas, mattresses, cabinets, and decoration scraps.

According to the demand of the market, Jiulong Machinery launched the large waste crusher. This equipment is mainly responsible for rough crushing. The materials after rough crushing can be screened through the next process, so that they can be processed in garbage treatment plants and filled in landfills. Resource reuse.

The size of the discharged material can be controlled according to the screen mesh;

Big brand motors have high energy efficiency and high efficiency;

PLC automatic control system;

Product Advantages

The large waste crusher uses the principle of mutual shearing and tearing between two relatively rotating knives to crush materials. Adopting "dual motors + double planetary reducers", it has strong power and high operating stability. It is often used in the fields of municipal solid waste disposal, resource reuse, waste incineration pretreatment and other fields. This equipment has the characteristics of low speed and high torque, large shearing force, good shredding effect, low noise and good stability. In addition, the equipment is equipped with magnetic separation that can sort waste wood, metal and other materials, which is more conducive to later recycling.

Bulky Waste Shredding-Reduction

1. Increase landfill utilization rate

2. Reduce compression truck load

3. Improve the appearance of the city

Bulky Waste Shredding-Recycling

Resource utilization income: as fuel income, scrap iron income, saving landfill costs

1. Waste turned into fuel

2. Waste iron wire can be re-smelted

Bulky Waste Shredding-Economical

Scope of application: Used mattresses, sofas, used furniture, refrigerators, home appliances, decoration waste, garden waste, packaging waste and other large household waste.

1. Save human resources

2. Save transportation costs

2. Waste Cartons

Kowloon's waste paper shredder has the characteristics of strong shredding ability, high efficiency, high output and low energy consumption. And it has strong power with high torque and low speed, and can even have strong ability to shred metal. The machinery and equipment produced by Jiulong adopts domestic advanced sound insulation technology, which has low noise, small vibration, and is very convenient and simple to operate. The waste paper product after being processed by a heavy-duty shredder is fibrous. The emergence of the waste paper shredder has greatly realized the recycling and reuse of waste paper, and has made a great contribution to the development of a circular economy and the construction of a conservation-oriented society. Once this important shredder equipment was put on the market, it was greatly Widespread concern.

The materials crushed by the shredder can be sent to the heavy-duty crusher through the conveyor for fine crushing. The crusher is composed of three parts: the machine body, the middle body and the lower body. The waste paper shredder is specially designed to crush various paper materials. It is suitable for refining various waste paper materials. It has the advantages of uniform discharge and controllable size. The design ideas and processing technology of the waste paper shredder can quickly crush, loosen and collect large-volume waste materials of any shape to ensure that environmental protection standards and waste recycling effects are met.

Product Advantages

The waste paper shredder is driven by double motors + double reducers, and the blades are made of alloy steel for coarse shredding and have high strength. The electrical part is controlled by PLC programming and has functions such as automatic detection and overload protection.

Broken Realm

Waste paper pulping equipment is widely used in the treatment of paper mill waste. It is suitable for crushing various waste cartons, packaging boxes, waste paper, wallpaper, newspapers, hard paper, corrugated paper, paper mill scraps, paper mill scraps, papermaking waste, and papermaking waste. Garbage, etc., and the size of the discharge material can be controlled and adjusted according to the screen, so as to quickly meet customer requirements.

3. Scrap Tires

Waste Tire Crusher Application

Waste bicycle tires, electric vehicle tires, motorcycle tires, tricycle tires, car tires, bus tires, off-road vehicle tires, agricultural and forestry machinery tires, light truck tires, engineering machinery tires, industrial vehicle tires, rickshaw tires, special Vehicle tires, aviation tires and other scrap tires and other rubber products.

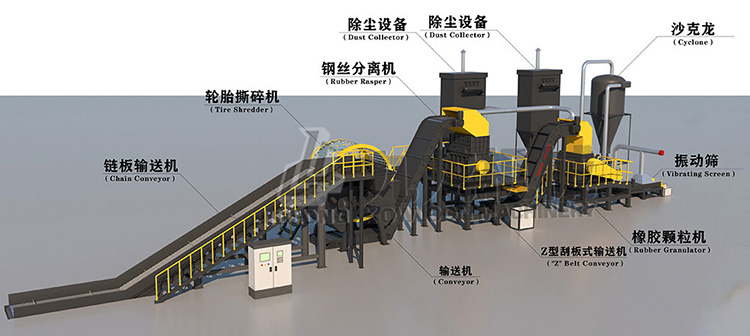

Major Equipment

For different tire characteristics and productivity requirements, equipment may include:

1. Fully automatic wire drawing machine: remove tire steel rims.

2. Conveying equipment: conveyor belts, screw conveyors and air pressure transmission systems.

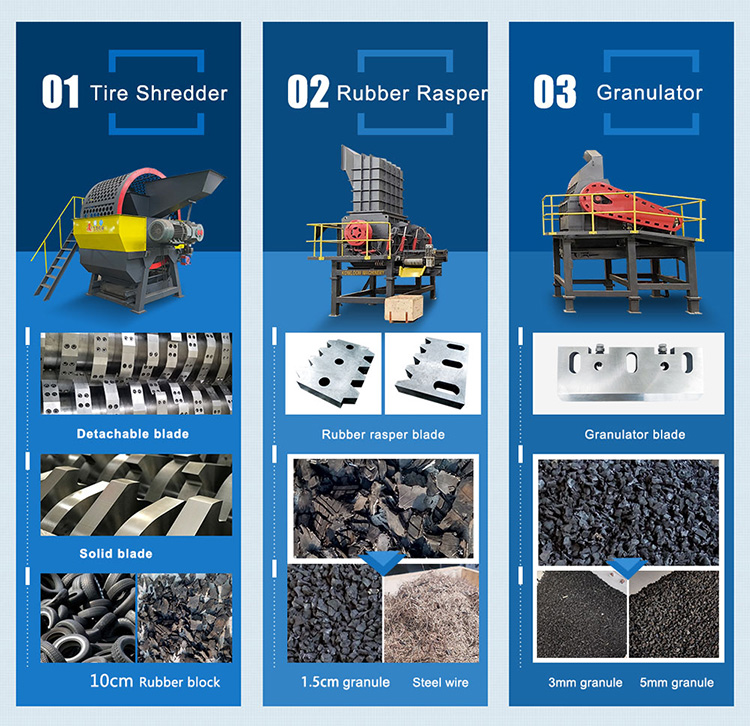

3. Tire shredder: shred tires into film (50mm-150mm).

4. Steel wire separator: separates rubber and steel wire and processes them into rubber particles (10mm-20mm).

5. Magnetic separator: separates steel wires from rubber and steel wire mixtures.

6. Rubber pellet machine: crush rubber particles to smaller sizes (1mm-7mm).

7. Vibrating screen: separates rubber particles of different sizes, and the oversized particles are sent back to the crusher for secondary crushing.

8. Fiber separator: removes foreign matter and fibers.

9. Secondary magnetic separator: remove any remaining small steel wires.

10. Grinding machine: Grind the particles into powder (30 mesh-100 mesh).

11. Fully automatic bagging system: put finished products into storage bags or packaging bags.

Application Scope

Produce rubber

Production of tires. Desulfurizing waste tire rubber through chemical methods to obtain rubber is an ancient method for comprehensive utilization of waste tires. This is a reasonable, scientific and widely used way to process waste tires for recycling, and has been adopted by countries around the world.

Production of Vulcanized Rubber Powder

The powder production industry has development potential, because it uses purely physical methods for processing, there is no waste gas and waste water pollution problem in production, and the resource utilization rate is very high. It is a waste tire resource processing method.

Waste Tire Paving

New technology, new life. The scrap tires used for road paving are called rubber asphalt.

Solid Waste Fuel

The embodiment of light and heat. Waste tires are a material with high calorific value. The calorific value per kilogram is 69% higher than that of wood, 10% higher than that of bituminous coal, and 4% higher than that of coke. The waste tires are crushed and then mixed with various combustible wastes according to the required proportion to prepare solid waste fuel (RDF), which can be injected into the blast furnace to replace coal, oil and coke as fuel for burning cement or to replace coal and thermal power generation. At the same time, this method also produces carbon black, a by-product, which can be used again as a reinforcing agent in the production of rubber products after activation.

Waste Tire Oil Refining

The waste tire refining equipment converts waste tires into 45-52% pyrolysis oil, 30%-35% carbon black and 10-15% steel wire through high-temperature pyrolysis. These cracked oils can be used in heavy industries, like cement plants, glass plants, boiler plants, etc. Carbon black can be used in cement plants and pressed into balls for sale.

Cracking Waste Tires

One of the main ways to convert it into new energy and new non-rubber resources is through catalytic pyrolysis, high and low temperature pyrolysis. Steel, carbon black, oil, gas, etc. can be extracted from waste tires at high temperatures. 35 kilograms of carbon black and 55 kilograms of fuel oil can be recovered from one ton of waste tires.

The rubber of tires has the characteristics of aging resistance, waterproofing and shock absorption, so the recycling of waste tires is mainly reflected in rubber particles and rubber powder. These materials can be used to modify asphalt, make waterproof materials, rubber floor tiles or rubber runways. The steel wires in tires can also be recycled and reused. If the tire recycling industry is developed on a large scale, it will also be in line with my country's sustainable development thinking, which can not only make profits but also solve the problems of resource pollution and waste.

Application

1. Sports venue paving: runways, campus sports fields, swimming pools and park trails, bowling alleys, sidewalks, kindergarten sports venues and entertainment fields, tennis and basketball courts.

2. Automotive industry: strips, train floor mats, brake disc ribbons, car and truck floors, brake bushings, sealing strips, buffers, shock absorbers, car body bottom seals and stainless steel materials, splash and soil protection , daily shipping raw materials, tires and their tire liners.

3. Construction/Equipment: Adhesives/Sealants, Companies, Bathroom Flooring, Insulation, Carpet Underlayment, Livestock Bedding, Extruded Products, Scrap Braking Surfaces, Molded Products, Coatings, Dams, Warehouses, Ponds, Waste Disposal Stations, brick roof underlayments and coverings, raised pattern floors, roof signs, sheets, waterproofing materials, shockproofing, gaskets, roof and wall waterproofing materials.

4. Geotechnical/asphalt applications: drainage pipes, rubberized asphalt for road and driveway paving, filters, soil conditioning/pavement coverings, porous flushing pipes, horse racing tracks, railway crossings, traffic/sidewalk barriers, Railway crack joint sealants road construction and repair marine.

5. Production and reuse of rubber: used to produce various rubber products.

Application of Tire Crusher Finished Product Fineness

8 to 20 mesh: Mainly used in runways, road cushions, pads, lawns, paving elastic layers, sports venue paving, etc.;

30~40 mesh: Mainly used in the production of reused rubber, modified rubber powder, paving, production of rubber sheets, etc.;

40~60 mesh: called fine rubber powder, used in rubber filling, plastic modification, etc.;

60~80 mesh: called fine rubber powder, mainly used in automobile tires, rubber products, building materials, etc.;

80~200 mesh: called fine rubber powder, mainly used in rubber products and military products

Applications

(1) Permeable asphalt additive, 3,500 tire recycling products can be used per kilometer of road;

(2) Guardrails can use 20,000 tire products per kilometer of 3 meters high;

(3) Playground surface (25mm), 50㎡ playground, 2,400 tire products can be used;

(4) On the surface of the game field, 300 tire products can be used for every 50 square meters of the game field;

(5) Sports field (15mm), 6,000 tire products can be used for every 3,000 square meters of field;

(6) For every 680 square meters of tennis court, 700 tire products can be used;

(7) For an indoor track, 1,300 tire products can be used for every 1,000 square meters;

(8) Tram roadbed can use 20,000 tire products per kilometer;

(9) Underground railways can use 2,000 tire products per kilometer