Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Application Materials :

Waste light and thin metal materials, cans, paint buckets, iron sheets, color steel tiles, etc.

Power :18.5-220 kw

Production :600-12000 kg/h

Product Details

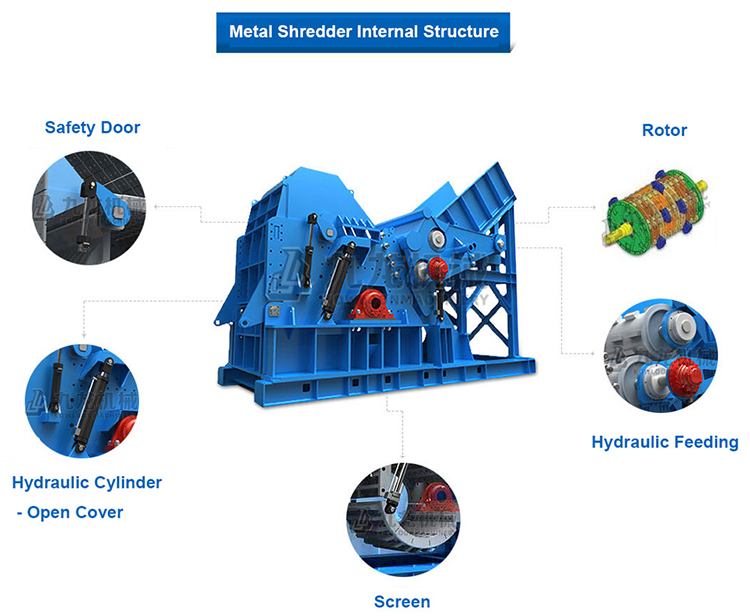

Scrap shredder is a shredding machine used to produce scrap shredded materials, mainly used for scrapping cars, scrapped household appliances and thin scrap steel machines.

Application Materials

Waste light and thin metal materials, cans, paint buckets, iron sheets, color steel tiles, etc.

Power

18.5-220kw

Production

600-12000kg/h

Product Description

Scrap shredder is mainly used for recycling scrap metal materials. The machine adopts a variety of hammer crushing principles to realize the shredding and recycling of scrap metal materials. Therefore, this machine is also called scrap iron shredder. Mainly used for scrapped cars, scrapped home appliances and thin scrap steel machines.

Applicable materials:

All kinds of scrap metal cans, motorcycle racks, bicycle racks, scrap home appliances, car shells, carriage boards, keel strips, paint buckets, scrap metal, color steel tiles, iron briquettes, scrap aluminum, scrap steel, scrap copper, coils Gates, scrap angle iron, etc.

The application status of scrap steel crushing production line in my country Since the 1990s, metal balers, crocodile shears and other equipment were generally used in my country to process scrap steel. The production needs of "feeding into the furnace", "energy saving and emission reduction" and "green steel". With the reform and deepening of my country's scrap supply and demand mechanism, the old "small and complete" model of "self-recycling, self-purchasing, and self-application" has been gradually broken by steel mills.

Scrap crusher is a professional equipment mainly used for scrap steel crushing. The head strike completes the crushing operation of the scrap, and crushes the scrap metal into particles, so as to facilitate the long-distance transportation and metallurgy of the scrap metal particles.

For large scrap steel components, our company can effectively provide assistance for the early crushing of the scrap steel shredder through the independent research and development of the supporting forced shortening and extrusion device, so as to improve the working effect of the scrap steel shredder. With the effective recycling and utilization of scrap metal resources, the mining consumption of natural mineral resources can be greatly reduced, so as to achieve the purpose of reducing land occupation, reducing total social energy consumption, saving investment, protecting the ecological environment, and improving labor production efficiency..

Application areas

Widely used in scrap steel recycling companies, metal smelting, construction industry, metal recycling industry, automobile recycling companies, etc.

Working principle

Scrap crushing is a processing method that uses a crusher to crush scrap, and uses a sorting system to sort the crushed scrap to obtain pure high-quality scrap. Its working principle is that under the continuous drive of high-speed and high-torque motor, the hammers on the rotor of the crusher take turns to hit the scrap steel in the cavity. The steel is then processed by the sorting equipment. The scrap steel crusher can peel off the surface dirt such as rust and paint on the surface of the scrap steel during the crushing process, and then under the action of the magnetic separation equipment, the pure crushed steel of the corresponding block size can be obtained. . It is especially effective in the treatment of unsorted and mixed low-quality scrap steel and scrapped cars, and it is a very realistic tool to change the quality of scrap steel at present.

Performance characteristics

1. The materials processed by the scrap crusher are neat in shape and similar in specifications, have a high heap specific gravity, and have less attachments;

2. The scrap crusher is installed with a foundation, and the startup is stable without too much noise;

3. The scrap crusher has a strong structure and densely clothed stiffening plates to ensure the strength of the box.

4. The scrap crusher can be equipped with conveyor belt feeding equipment;

5. The blade of the scrap crusher is a meshing blade made of high alloy, which has a good crushing effect on any high-hardness material.

| Model | JLHC-200 | JLHC-315——420HP | JLHC-450——600HP |

|---|---|---|---|

| Thickness of case plate | 30mm | 40mm | 50mm |

| Thickness of screen | 60mm, material: cast steel, mesh 65*85mm | 100mm, material: cast steel, mesh 65*85mm | 100mm, material: cast steel, mesh 65*85mm |

| Thickness of edge lining plate | 40mm | 50mm | 60mm |

| Main shaft Diameter | 200mm,material:40Cr | 250mm,material:40Cr | 280mm,material:40Cr |

| Rotor disc | φ800mm, thickness 50mm, welding wear layer | φ900mm, thickness 60mm, welding wear layer | φ1200mm, thickness 80mm, welding wear layer |

| Hammer | 10pcs, material: 13Cr2Mn, unit weight: 35KG | 10pcs, material: 13Cr2Mn, unit weight: 45KG | 14pcs, material: 13Cr2Mn, unit weight: 75KG |

| Thickness of Forced feed plate | 16mm, hydraulic system | 20mm, hydraulic system | 20mm, hydraulic system |

| Motor/control cabinet | 8P-200kw (1pcs), brand: WNM Soft starting cabinet, electrical components: Chint/Delixi | 8P-315kw (1pcs), brand: Simo - Slip Ring motorcyclo motor water resistance starting cabinet, electrical components: Chint/Delixi | 8P-450kw (1pcs), brand: Simo - Slip Ring motorcyclo motor water resistance starting cabinet, electrical components: Chint/Delixi |

| Feed chain conveyor | 9000*1200mm,1pcs, power:7.5KW | 12000*1400mm,1pcs, power:11KW | 12000*1600mm,1pcs, power:11KW |

| Vibrating discharge machine | 2500*1000mm,1pcs, power:3KW | 2500*1000mm,1pcs, power:3KW | 3000*1200mm,1pcs, power:4KW |

| Discharge conveyor | 1000*6000mm,1pcs, power:4KW | 1000*6000mm,1pcs, power:4KW | 1000*6000mm,1pcs, power:4KW |

| Magnetic separation vibration feeder | 2000*1000mm,1pcs, power: 3KW | 2000*1200mm,1pcs, power: 4KW | 2000*1200mm,1pcs, power: 4KW |

| Drum magnetic separator | 1000*650mm1pcs, power: 5.5KW | 800*1000mm 1pcs, power: 7.5KW | 1000*1000mm1pcs, power: 7.5KW |

| Output conveyor | 800*8000mm1pcs, power: 4kw | 800*8000mm1pcs, power: 4KW | 1000*8000mm1pcs, power: 5.5KW |

| Slag removal conveyor | 500*8000mm1pcs, power: 3kw | 600*8000mm1pcs, power: 3KW | 650*8000mm1pcs, power: 4KW |

| DMC-120 Filter bag type dust collector/Cyclone/pipe/fan | 1set power: 7.5KW | 1set power: 11KW | 1set power: 22KW |

| Capacity | 4-6t/h | 8-10t/h | 10-15t/h |