Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Product Advantages

1. Strong magnetic field;

2. Large range of sorting particle size;

3. High sorting rate;

4. Safe and easy to use;

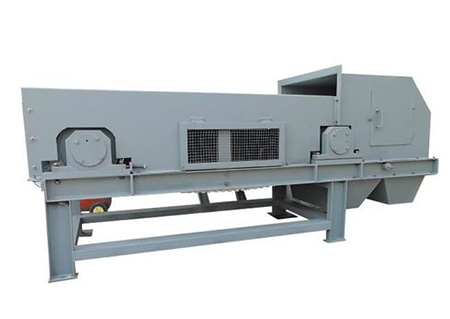

Eddy Current Separator Machine

Eddy current sorting machine is an effective solid waste separation equipment. It is mainly used for sorting non-ferrous metals in industrial and domestic waste. It is widely used in electronic waste processing, domestic waste sorting, scrap car dismantling and recycling, and scrap electrical appliances. Industries such as recycling, industrial slag recycling and material handling in the non-ferrous metal processing industry;

When the eddy current is working, a high-frequency alternating strong magnetic field is generated on the surface of the sorting magnetic roller. When conductive non-ferrous metals pass through the magnetic field, eddy currents will be induced in the non-ferrous metals. This eddy current itself will generate the original magnetic field. In the opposite magnetic field, non-ferrous metals (copper and aluminum) will leap forward along their transport direction due to the repulsive force of the magnetic field, achieving separation from other non-metallic substances to achieve the purpose of sorting.

Product Advantages

1. Strong magnetic field;

Using permanent magnet NdFeB as the magnet source, the magnetic force is extremely strong and the magnetism is stable and long-lasting;

2. Large range of sorting particle size;

Non-magnetic non-ferrous metals with particle sizes larger than 2mm can be sorted;

3. High sorting rate;

The repulsive force is strong and adjustable, and the material adaptability is strong, and the sorting rate can reach up to 98%;

4. Safe and easy to use;

The structure is compact and stable, easy to install and use, and easy to maintain;

| MODEL | Feeding Width(mm) | Feeding length(mm) | Feed particles |

Capacity (cbm/h) |

Power(KW) | Weight(KG) | Length(mm) | Width(mm) | High(mm) |

|---|---|---|---|---|---|---|---|---|---|

| JL-W-6.5 | 400 | 1500 | >=1 sqmm | 15 | 5.9 | 950 | 4600 | 1423 | 1200 |

| JL-W-8 | 600 | 1500 | >=1 sqmm | 20 | 5.9 | 1225 | 4600 | 1623 | 1200 |

| JL-W-10 | 800 | 1500 | >=1 sqmm | 25 | 6.3 | 1555 | 4600 | 1823 | 1200 |

| JL-W-12 | 1000 | 1500 | >=1 sqmm | 30 | 7.0 | 1875 | 4600 | 2023 | 1200 |