Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Article published:2024-01-22

What are the requirements for the material and specifications of the blades of plastic shredders?

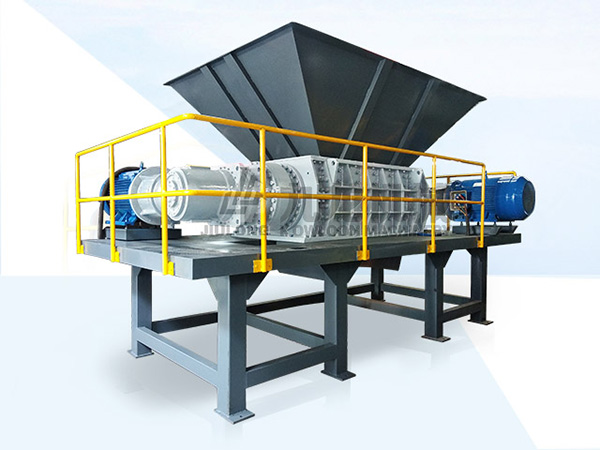

The core component of the plastic shredder is the blade. Good blade material and reasonable specification design can increase the use value of the shredder. Commonly used shredders include single-shaft, double-shaft, and four-shaft. The blade material of the single-shaft shredder is SKD-11, which has higher hardness and wear resistance. Because it is a single-shaft, the power is also relatively high. Small, so the output is relatively low, suitable for small business investment. The blades of plastic shredders, which are representative of dual-shaft shredders, are made of Cr12MoV. The number and shape of the claws are designed according to the machine, ranging from as few as two claws to as many as twelve claws. And its shape also has a certain design, which should be selected according to different waste materials.

Generally, the distance between the shredder blade and the blade determines the shape and size of the shredded material. If the user purchases the shredder mainly to shred waste plastic, then the shape and size of the shredded plastic must be determined. Report it to the manufacturer, and the manufacturer will select the blade according to the customer's requirements. For shredding non-metallic materials such as plastics, you must choose a blade with higher hardness. Only scientific blade selection can bring higher shredding efficiency to your shredder.

What should we pay attention to in the daily maintenance of plastic shredder equipment?

Many users always have doubts about the quality of the equipment when purchasing plastic shredder equipment. But I bought the equipment and didn't pay attention to the daily care of the equipment. After using the equipment for a period of time, some problems appeared, so I went to the manufacturer to ask for compensation and resolution. No matter how good the equipment is, if it is not taken care of, its service life will be greatly shortened. Equipment is just like people. If we don’t pay attention to nutrition and care, how can we grow up healthily?

1. Before starting the preparation work, first check whether the accessories are severely worn, whether they can work normally, and whether the screws and bolts are loose. You can also gently pull the belt with your hands to test the rotation to see if there is any collision with the shell. If everything is normal You can feed materials for production.

2. When feeding, the material must be fed evenly and uniformly to ensure the crushing quality and normal consumption of the equipment. At the same time, it is strictly forbidden to overload the motor to ensure the normal operation of the equipment.

3. In addition to always paying attention to the fastening of various accessories, you should also pay attention to the wear of wearing parts. If there is serious wear, replace it in time to avoid the equipment being unable to work.

4. Don’t neglect the filling of lubricating oil. Appropriate adding of lubricating oil can not only reduce the wear and tear of the equipment, but also improve the working efficiency of the plastic shredder. Good lubrication can also ensure the normal operation of the equipment.

You need to know these tips when buying a plastic shredder

Nowadays, everything requires skills, and of course the same goes for buying a plastic shredder. The emergence of plastic shredders not only solves the problem of white pollution, but also effectively saves plastic resources so that they can be recycled. With the popularity of plastic shredder equipment, a large number of shredder manufacturers have emerged. Therefore, we need to pay special attention when selecting shredder equipment. Below, the editor will share with you some tips on selecting plastic shredders.

1. When we choose a plastic shredder, we go to the manufacturer for inspection. This is an effective way to directly understand the strength of the manufacturer. Especially under the impact of Internet sales, because the network has a certain virtuality, we go to the site to conduct on-site inspections. , is an effective way to purchase plastic shredder equipment.

2. You cannot buy plastic shredder equipment that is too low-priced, because there are many leather bag companies in the shredder market. They do not have actual production workshops and mainly rely on switching between users and manufacturers to make the price difference. Such manufacturers have relatively weak competition in the market, so they use low prices to attract users. In this way, not only the quality of the purchased equipment cannot be guaranteed, but there is also no after-sales service. Once there is a problem with the equipment, it cannot be effectively solved.

3. Clarify your own output and shredded materials. When users choose a plastic shredder, they should choose it based on their own output and usage, because there are many models of plastic shredders. Although the manufacturer will recommend a suitable model based on the user's description, we must also do it I know it well. And regarding the after-sales issues of the equipment, no matter the quality of the plastic shredder, once a problem occurs during later use, after-sales manufacturers will help users to solve it together.

What should be done before using the plastic shredder?

As the old saying goes, if you sharpen your weapon quickly, it will be useless. We should do the preparations before doing any work, so that we can complete it very well. Of course, the same is true for plastic shredders. Many users do not prepare the equipment before starting it up before using the plastic shredder, resulting in serious damage to the equipment after a long period of use. This not only affects the life of the plastic shredder, but also affects the life of the plastic shredder. Will affect its work efficiency and output. The following editor will analyze for you what should be done before the plastic shredder works?

When the plastic shredder is working, it cannot be put into production as soon as it is turned on. This will cause harm to the motor of the plastic shredder. We all know that motors need to be preheated before use, because the motor speed is relatively high. The speed of a high-power motor can reach several thousand revolutions, and such a high speed actually takes time to generate. Therefore, before using the plastic shredder, we can start it and preheat it. When the plastic shredder gradually stabilizes, we can put in materials for production.

For users of plastic shredders, the choice of model is very important. For plastic shredders with small models, the output and shredding capacity may not be enough, and thus cannot meet daily production needs. Therefore, when we buy When buying a plastic shredder, you should tell the manufacturer your needs and shredding materials, so that the manufacturer can recommend suitable plastic shredder equipment to you to facilitate the user's later application.