Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Article published:2024-01-31

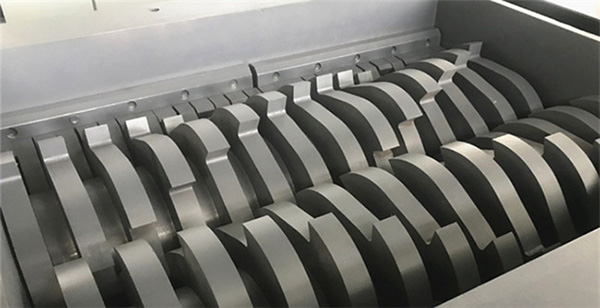

Double-shaft shredders are used in the treatment of many wastes

The double-shaft shredder equipment produced is being processed by more and more waste, and resources are reused as auxiliary production equipment. The production of the industry has made great progress. Resource recycling is favored by more and more people. Resource reuse is A good energy-saving project, the rise of the industry and the increase in industry demand have made the demand for double-shaft shredders continue to rise.

1. The production efficiency of equipment has improved. There is a huge demand for more and more waste treatment. It is necessary to select a high-efficiency double-shaft shredder to keep up with the pace of industry production. The double-shaft shredder meets user needs and uses sophisticated knives. *, motors, bearings and other parts, high-quality parts are assembled to form a high-power double-shaft shredder.

2. Double-shaft shredder equipment

With the improvement of people's living standards and convenient lifestyle, it is also harmful to our health. Plastic packaging bags can be seen everywhere. Double-shaft shredders solve "white pollution". The increase of cars on the road makes it easier for us to go out. At the same time, A lot of tires are scrapped every year, and the dual-shaft shredder solves the "black pollution". The double-shaft shredder can be said to be a truly safe equipment, and it is an ideal equipment under the development of the industry and the resource situation.

3. Economical double-shaft shredder equipment

The double-shaft shredder saves the waste of some renewable resources in our country. At the same time, although the double-shaft shredder equipment produces efficient work during the operation project, it does not consume much power energy. The special design of the motor equipment , only a small amount of power is required to drive the operation of the entire device. Low consumption, high performance and guaranteed double-shaft shredder.

Double-shaft metal shredder is one of the large-scale metal crushing equipment

The double-shaft metal shredder is a large-scale crushing equipment produced in response to the market. The equipment configuration of the machine consists of a feeding conveyor, a metal crushing host, a discharging conveyor, a sorting system, a centralized dust removal system, a control distribution cabinet and other equipment , this machine can achieve one-time crushing and kneading processing of scrap iron sheets, metal briquettes, bicycles, metal, frame briquettes, battery cars, color steel tiles, paint buckets, flower boxes, cans and other light and thin scraps, so as to realize the paint in scrap steel. , metals and non-metals and the separation of aluminum, copper and iron in metals to improve the quality of steelmaking charges.

The metal after modified scrap steel crushing has the advantages of high density, high material purity, convenient transportation, and high recycling value. Double shaft metal shredder product features:

1. Various crushing cavity types, flexible application and strong adaptability.

2. Thin oil lubrication, reliability, extended service life.

3. Equipped with a special thin oil lubrication system to ensure the flow of lubricating oil between components and the components can be fully lubricated.

4. Scrap cars are put in from the top inlet and fall into the middle parts of the rotating rotor. The falling materials are thrown out at high speed under the strong centrifugal force of the rotor and hit the impact plate inside the main machine to be broken.

5. Crushing principle and technical parameters, reliable operation and low operating cost.

The dual-shaft metal shredder is suitable for materials: scrap cars, car compartments, rolling shutters, color steel tiles, metal, car frames, scrap metal, car skins, car compartment panels and other scrap metal. Product advantages after crushing by double-shaft metal shredder:

1. Pellets are easy to transport, which can effectively reduce transportation costs and increase transportation efficiency;

2. The sales price of metal particles is much higher than the price of scrap iron and scrap aluminum;

3. Metal particles are easier to store than metal, which can save a lot of warehouse space;

4. Metal particles greatly facilitate use and reprocessing.

How to grind and repair shredder blade wear

The shredder blade is one of the important accessories of the shredder. The quality of the shredder blade directly affects the machine's processing cycle of waste materials. According to the classification of the shredder, the shredder blade is divided into single-shaft shredders. Blades and multi-shaft shredder blades. As an important crushing knife on the shredder. According to the shredder structure classification, shredder blades can be divided into single-shaft shredder blades and multi-shaft shredder blades (including dual-shaft shredder blades and four-shaft shredder blades).

The shredder blade is the soul of the entire equipment. If it is operated improperly, the blade wear will be serious and the service life of the machine will be shortened. So the shredder blade wears quickly due to incorrect operation.

1. Abnormal reasons why the shredder blade wears too fast

1. Improper heat treatment on the surface of the equipment. Because the hammer head is made of steel and the head has been carburized and quenched. If the heat treatment is improper, it will wear out quickly during use.

2. The thickness of the shredder blade is small, and a rectangular double-pin hole hammer head is commonly used. Its service life is 200 to 500 hours. Although the small thickness can reduce the weight and increase the shredding productivity, the service life is short and the shredding performance is generally limited. The machine hammer blade should be 2~3mm, and the hammer blade should be 6~8mm for shredding other hard materials.

3. The air suction volume is too large. Equipment generally adopts suction methods to reduce the temperature and humidity inside the machine and prevent dust from leaking out. However, too much air suction volume will also cause uneven wear of the hammer head, so the air volume should be appropriately controlled.

4. The gap between the hammer head and the screen is too small. It should generally be kept at 4~12mm and for hard materials is 10~14mm.

2. How to polish the plastic shredder blade*

The plastic shredder blade will become dull after a period of use, so how to polish it again?

1. Grinding with a surface grinder: The grinding effect of a surface grinder is very good. Using a surface grinder to grind the blade of the metal shredder can not only effectively protect the blade, but also the final effect is very good. Grinding Quality guaranteed.

2. Use grinding wheels for grinding: I believe many people are familiar with grinding wheels. Grinding wheels are used very frequently in daily life, so using grinding wheels to polish the blades of plastic shredder equipment is also a good choice. , the familiarity of manual operation also gives us a good grasp of the polishing process.

3. Use an automatic knife sharpener to grind: If you want to save a little effort, an automatic grinder is undoubtedly a good choice, and the operation is simple and easy to master.

Plastic shredder equipment is a new type of safe machinery and equipment designed for crushing scrap metal; it is mainly suitable for paint buckets, cans, colored steel tiles, bicycles, scrapped cars and other materials.

Dual-shaft shredder solves the problem of urban waste disposal

Environmental engineering is the prerequisite for current social development and economic development. All development needs to be based on environmental engineering to expand production and develop. Cities are an ideal choice for people to live in, but the disposal of domestic waste generated every day in urban life is a headache. In the past, people just threw the garbage generated every day into the trash can. , Natural Recycling has cleaners who collect and dispose of garbage, but they never care about where the domestic garbage goes.

Burial has been the final destination of domestic waste for many years. As time goes by, the problem of soil pollution caused by landfill has gradually surfaced.

Finding suitable domestic waste disposal methods in continuous practice is a very important thing at the moment. With the independent efforts of relevant people in the industry, domestic waste classification, shredding, recycling and reuse are gradually improving urban domestic waste treatment methods. In this gradually improving urban domestic waste disposal plan, the dual-shaft shredder has become a must-have. The volume of domestic waste processed by the double-shaft shredder has become smaller, which is particularly important in transportation. You see, loading large volumes of domestic waste into transport vehicles is time-consuming and labor-intensive. It can only be transported at one time. It's such a small space. It looks quite big when you look at the space, but actually you can't fit anything in it.

The double-shaft garbage shredder meets customer needs and is favored

The double-shaft garbage shredder is a type of solid waste shredder with a wide range of uses. It is mainly used for solid waste such as domestic waste, large waste, electronic waste, kitchen waste, and industrial waste. It is especially suitable for shredding garbage. The double-shaft garbage shredder is equipped with a wedge or gasket adjustment device. The top of the wedge device is equipped with an adjusting bolt. When the adjusting bolt pulls the wedge upward, the wedge pulls the movable roller out of the fixed wheel, that is, between the two rollers. The gap becomes larger and the discharge particle size becomes larger.

The double-shaft garbage shredder is a shredding and volume reduction equipment specially developed for the large-scale garbage treatment industry. This series of products adopts a low-speed and high-torque design and has the characteristics of large shearing force, good shredding effect, low noise, and high stability.

The double-shaft garbage shredder is mainly used to shred and process large garbage such as waste mattresses, sofas, tables and chairs, and waste wood. The shredded materials have uniform particle size, which is convenient for transportation, transportation, resource reuse, incineration and power generation and other terminal processing. It is the core equipment to solve the problem of low-value solid waste treatment.

Double-shaft garbage shredders of different specifications use different tools when processing various materials and raw materials, and the number, materials and shapes of the tools are also different. The tools used in the double-shaft garbage shredder can be disassembled and replaced. In recent years, the double-shaft garbage shredder has become a key equipment that can meet the shredding requirements of different materials, so it is favored by users.