Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Article published:2024-02-21

The double-shaft shredder is the messenger of circular economy and environmental protection

When the garbage generated in daily life enters the shredding bin, the shredder's blades and sticks will squeeze and tear each other to achieve the effect of shredding the materials. The domestic waste shredder equipment is driven by a planetary gear reducer, and the blades are made of high-strength alloy steel, which has strong wear resistance and high strength, and has the functions of tearing, squeezing, and biting. In addition, the output of the domestic waste shredder is also very high. The simple and easy-to-learn operation solves the troubles caused by domestic waste, benefits mankind, and protects the environment.

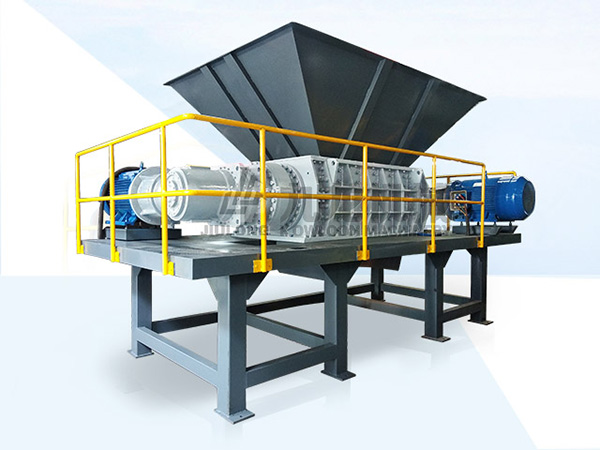

The double-shaft shredder is also called a shear shredder, which is suitable for shredding and decomposing solid waste. The two cutter shafts of the double-shaft shredder rotate in opposite directions, and the material is refined and decomposed through shearing, tearing, and squeezing of the cutter shafts. The dual-shaft shredder introduces the design, manufacturing and use experience of European dual-shaft shearing solid waste shredders to provide a strong, efficient and stable dual-shaft shredder for the domestic market.

The dual-shaft shredder is also called a dual-shaft shearing crusher. It uses the working principle of interaction between knives to process materials. It can be used for the disposal of urban solid waste, agricultural solid waste, and industrial solid waste. It can also process soft and hard materials. All have good breaking effects. The equipment adopts low-speed, high-torque design and has the characteristics of large shearing force, good shredding effect, low noise and good stability. This series of shredders are widely used in the recycling of waste plastics, waste rubber, wood and other large-volume wastes. Shearing by this machine can increase the packing density of materials and reduce transportation costs. After crushing, the materials can be further processed through other equipment, such as material separation, cleaning, etc.

The double-shaft shredder changes the traditional linear economic flow model of "resource products and waste" to form a material closed-loop flow growth model of "waste products regenerating resources", and reintegrates the waste generated in people's production and living processes into human production. , the recycling process of life, and transformed into useful material products. This is a circular economy development model.

Dual-shaft shredder opens the era of intelligent shredding of industrial solid waste

The dual-shaft shredder, also called the dual-shaft shearing crusher, is a highly automated and intelligent regeneration crushing equipment designed by Zhongan Environmental Protection based on the characteristics of industrial solid waste. The dual-shaft shredder has been continuously innovated and upgraded. It has better performance advantages and better user experience, and is often used for solid waste reduction, harmlessness, and resource treatment.

Double-shaft shredders are widely used:

The dual-shaft shredder was originally designed to shred domestic waste and industrial waste. However, through the unremitting efforts of Zhongan Environmental Protection's R&D personnel, the equipment has been continuously modified and upgraded, and now it can handle more businesses, such as bulky waste, kitchen waste, etc. Crushing sites such as residual garbage, garden waste, electronic waste, medical waste, decoration waste, metal waste, etc. are all battlefields for dual-shaft shredders.

The dual-shaft shredder has intelligent features:

The dual-shaft shredder adopts an intelligent monitoring system to achieve intelligent operation, safety interlocking, collaborative operation and maintenance, digital management, multiple protections, and has multiple functions such as information transmission, real-time monitoring, and abnormal alarms. Equipped with an electrical automatic control system, it has start, stop, reversal and overload automatic reversal control functions to reduce equipment failure rates. In addition, a series of high-standard configurations such as automatic lubrication devices and hydraulic pressing devices make the double-axis tearing machine The crusher works with twice the result with half the effort.

Five advantages of double-shaft shredder

1. Integral tool box design: processed in one piece, with high mechanical strength, high stability and reliability; overall annealing treatment, longer service life.

2. The raw materials of the cutting tools are made of high-strength and wear-resistant materials: processed by high-precision machine tools, the mechanical properties are significantly improved and the service life is greatly extended. The tool can be repaired by welding multiple times to save costs.

3. High-strength spindle: The spindle is made of special material and has undergone multiple heat treatments and high-precision processing. It has good mechanical strength and long service life.

4. Imported bearings and multiple combined seals: dustproof, waterproof and antifouling, ensuring the continuous and stable operation of the machine.

5. Independent detachable fixed knife design: The anti-winding and surrounding fixed knife design prevents material from wrapping around and crashing. Each fixed knife can be independently disassembled and installed, and can be quickly disassembled in a short time, which greatly reduces the workload of workers and improves production continuity. sex.

Waste textile fabric crushing + briquetting production line, a new choice for waste resource recycling

Waste cloth, waste textiles, clothing, leather scraps, shoe scraps, etc. contain a certain amount of organic and fibrous substances with relatively high calorific value. The waste cloth can be shredded and processed centrally as fuel raw materials. The commonly used process is classification-top Material - shredding - secondary shredding - uniform distribution in the silo - compression molding - preparation and discharging.

Application fields of waste textile cloth crushing production line:

The waste textile and fabric crushing production line is especially suitable for crushing all kinds of waste clothes, waste cloth, machine head materials, all kinds of waste scraps, all kinds of waste scraps, waste leather, cowhide, fiber, old shoes, carpets, quilts, clothing and other Waste household items, office supplies, etc.

The process of making fuel from waste cloth

The waste cloth is transported to the double-shaft crusher through the conveyor for coarse crushing to reduce the volume of the material to facilitate subsequent processing; the crushed material enters the magnetic separator to separate the iron material for recycling; after separation, the waste cloth continues to enter the crusher , crushed into ideal size; the finely crushed materials are extruded into RDF high-density particles through the RDF molding machine, which are used as fuel for combustion and power generation in power plants. In order to avoid dust pollution caused during the processing, the entire production line is equipped with The dust removal system can collect and reduce dust from the crushing and sorting processes to prevent secondary pollution.

Special anti-winding design for waste textile crusher

The dual-shaft shearing and crushing machine (waste textile and scrap material crusher, dual-shaft shredder) is designed with a special anti-winding fixed knife based on the characteristics of waste textiles, cloth, scrap materials and other materials and common problems in production, which can effectively deal with the materials. To solve the problem of winding knives, improve crushing efficiency and equipment stability; the fixed knives are made of high-strength wear-resistant steel plates, which have the characteristics of high strength, good toughness, and not easy to break. It can prevent various types of plastic bags, garbage bags and other packaging from being entangled. When encountering unbreakable objects, the equipment will protect itself to quickly clear obstacles. The shredder shreds it into fuel, which not only solves a large amount of cloth waste, but also saves the coal consumption of power plants, killing two birds with one stone.