Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Article published:2024-02-20

Comparison of the advantages and disadvantages of single-shaft shredder and double-shaft shredder

Both single-shaft shredders and double-shaft shredders are commonly used equipment for processing waste. The main unit of the single-shaft shredder adopts a hydraulic pushing system and a single hob design, which can easily shred waste paper, machine head materials, cloth, Shred plastic film and other waste materials into small pieces. The main machine of the double-shaft shredder is composed of two oppositely rotating cutter shafts, which can tear and shear the materials. It can be used to process vehicle frames, wheel hubs, scrap wires, etc. The shredded waste materials such as color steel tiles and paint buckets reduce transportation costs and facilitate subsequent processing and recycling. The shredder is one of the important equipment in the waste recycling, renewable resource and environmental protection industries, and plays a positive role in reducing resource waste and environmental pollution. Next, let’s take a look at the advantages and disadvantages of single-shaft shredders and double-shaft shredders.

Single shaft shredder

1. The single-shaft shredder is designed to process materials in a targeted manner, and the corresponding processing range is relatively narrow, while the double-shaft shredder is almost universal and can handle many materials and has a wide range of processing.

2. The double-shaft shredder is suitable for processing some harder materials, such as color steel tiles, iron sheets, scrap furniture, etc. These materials are more difficult to shred. The single-shaft shredder is suitable for processing some softer materials, such as plastics. , rubber head material, rubber, sponge, waste paper, etc.

3. In terms of shredding effect, the effect of the dual-shaft shredder is better than that of the single-shaft shredder, because the dual-shaft shredder shreds materials from different directions, and the single-shaft shredder shreds the materials from different directions. There is only one knife axis, and the shredding effect is relatively weak.

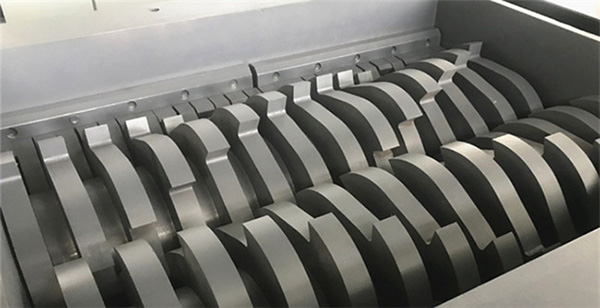

Double shaft shredder

4. Single-shaft shredder machines are usually smaller than double-shaft shredders, taking up less space. The structure of a cutter shaft is more convenient for maintenance, and it is also convenient to replace and adjust the blade.

5. The double-shaft shredder has two rotating shafts, which runs more smoothly and makes less noise. Since the load is distributed on the two cutter shafts, the wear of a certain cutter shaft is reduced, so it is used The lifespan will also be longer.

In fact, which shredder to choose mainly depends on the materials to be processed. For hard materials or large quantities of materials, a double-shaft shredder will be better. For soft materials, a single-shaft shredder will be more cost-effective. Each has its own advantages and disadvantages. Depending on different actual needs and application scenarios, single-shaft shredders and double-shaft shredders are both shredder equipment for processing solid waste and realizing resource recycling. When purchasing, you also need to consider the processing capacity and production capacity of the machine. Requirements, power consumption and other factors, fully communicate with the manufacturer before purchasing to better choose a suitable shredder.