Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Article published:2023-12-28

How to solve the problem of serious blade wear of metal shredder?

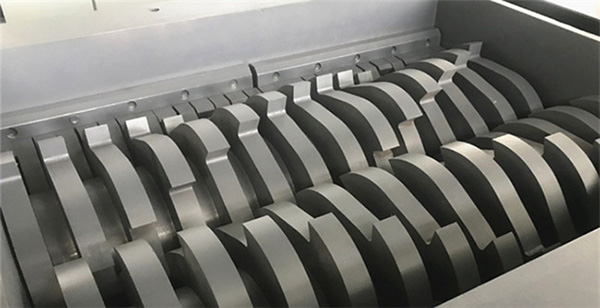

As a mechanical equipment with a very wide range of applications, the metal shredder has solved many problems caused by too much scrap metal in our lives. However, as the core accessory of the equipment, the blade is often used during work due to its characteristics. It will be subject to wear, and when we use it, we suddenly find that the production efficiency cannot meet the demand. It should be that the wear of the blade is more serious. How should we solve this problem at this time? Let’s follow the professional manufacturers to find out.

How to solve blade wear

If the wear of the shredder blade is not very serious, it can be regrinded. The regrinding method of the metal shredder blade is different from other types of blades. For other types of blades, grinders are basically used to grind the flat or edge parts. Repair and grinding. Due to the particularity of its structure, the blade of the metal shredder can only be repaired along the arc of the blade during repair. This will cause less loss to the blade and is also an effective repair method.

If the wear is too serious, it needs to be replaced. When replacing, pay attention to the model of the blade, and adjust the height, vertical height, etc. of the blade. After adjustment, tighten the bolt of the tool immediately to prevent certain damage caused by blade movement. , then add lubricating oil and start the machine for test. If everything is normal, you can start working.

How to increase shredder output

The first thing to do to increase output is to prepare before starting the machine. Before starting work, the shredder should be inspected. After the inspection is correct, it can be started. The machine should be idle and preheated for two minutes before starting the feeding work. When shredding materials, choose the same kind of materials. Do not shred the wood and then shred the metal. When feeding, feed the materials evenly. Do not put in a lot of materials at one time. This may cause the machine to jam. When shutting down, wait until all materials are discharged before shutting down the equipment. The last step is maintenance and lubrication. Effective maintenance of the shredder can greatly improve the production efficiency of the shredder and increase output.

Problems encountered during the use of double-shaft shredder and their solutions

With the rapid development of society, double-shaft shredders have become common equipment on the market. As the number of users using crushers continues to increase, more and more problems are encountered. No matter which kind of mechanical equipment on the market has been working for a long time or is operated improperly, it will break down. So what are the common faults of double-shaft shredder equipment during use, and how to solve them?

1. Dual-shaft shredder: When the motor rotor and the dual-shaft shredder rotor are not concentric, the machine will produce overall vibration. You can pad copper sheet on the bottom surface of the bearing seat, or add an adjustable wedge iron at the bottom of the bearing. This fault can be eliminated by ensuring that the two shaft heads are concentric.

2. The local vibration of the rotor crushing chamber inside the double-shaft shredder is relatively large. The reason is that the connection between the coupling and the rotor is not concentric or the quality of the flat hammer inside the rotor is uneven. Corresponding methods can be adopted to adjust the connection between the coupling and the motor according to different types of couplings: when the quality of the hammer blades is uneven, each set of hammer blades must be re-selected so that the relatively symmetrical hammer blades of the dual-shaft shredder system The anchor bolts are loose or the foundation is weak. When installing or repairing, the anchor bolts must be tightened evenly. A shock-absorbing device must be installed between the anchor foundation and the crusher to reduce vibration. If the twin-shaft shredder anchor bolts When loose, the body may vibrate strongly.

3. When there is debris in the blade of the double-shaft shredder or in the crushing chamber, it will also cause vibration. To eliminate this fault, you need to clean the crushing chamber and clean up the debris in the crushing chamber. In fact, when these minor faults occur, if the corresponding causes can be found, these minor faults can be accurately eliminated. Of course, I also have a close relationship with the operating technicians. I understand the problems related to the double-shaft shredder and can well solve any failures of the double-shaft shredder. Keeping the double-shaft shredder equipment in good working condition is an important principle adhered to by employees.